Accesories

minileiste X5 series

Tool-free, quick and easy

The transition profiles from minileiste can be installed easily , without tools and without visible fastening points: no drilling, no screwing, no hammering, no dirt, no noise, no annoyance. Irregularities in the floor can be easily compensated for by simply attaching additional mounting clips if necessary.

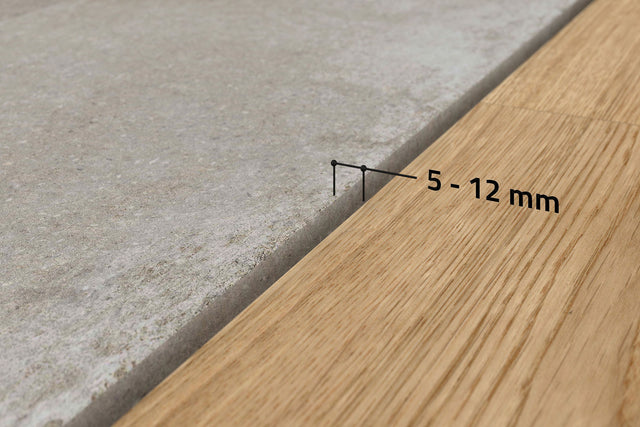

Step 1

The width of the connection joint should be between 5 and 12 mm. The thickness of the flooring must also be taken into account. Type X5 systems can be used with a minimum floor covering thickness of 5 mm.

Step 2

The dimensions for the profile cuts are taken from the floor covering.

Any mitre cuts are taken into account.

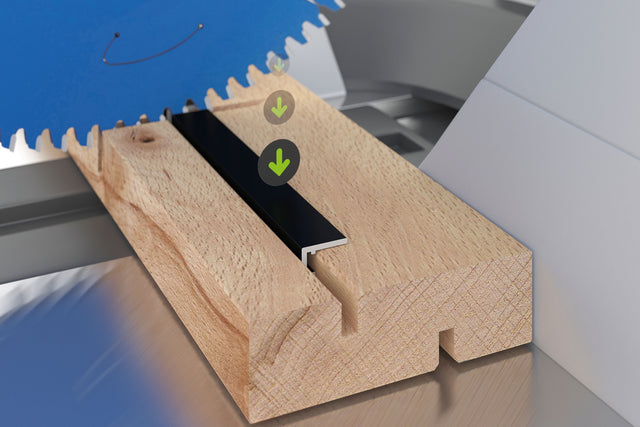

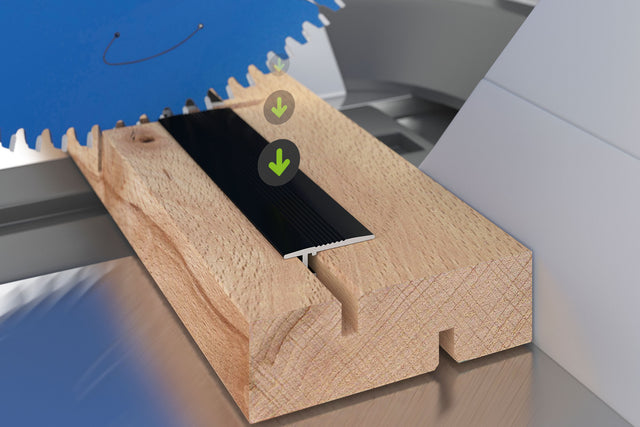

Step 3

The profiles are cut to length. The profile is securely positioned in the cutting aid. This prevents the profile from jamming during the cutting process.

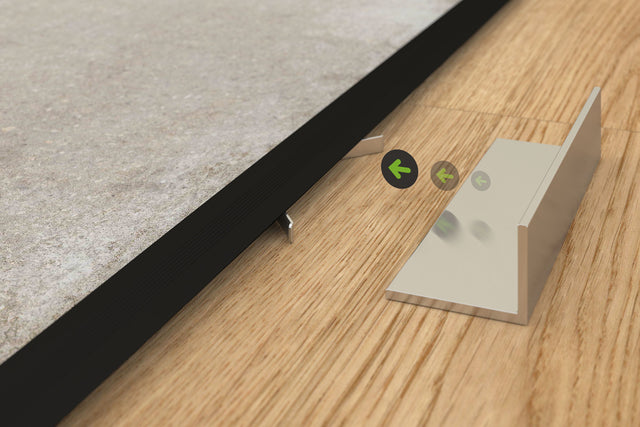

Step 4

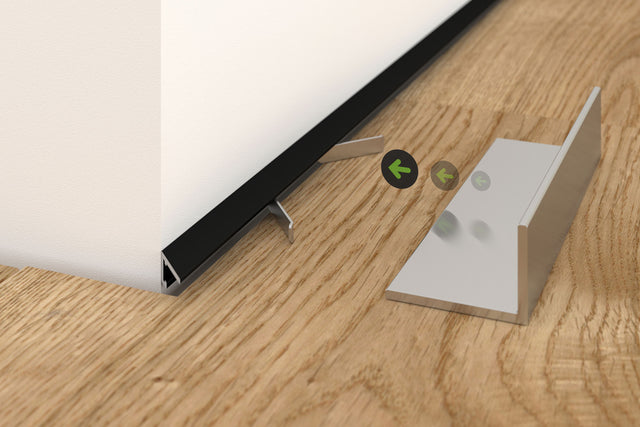

The mounting clips are pushed into the transition profile on the front. Attention: Two opposite shoulders are worked into the transition profile, between which the mounting clips are easily guided.

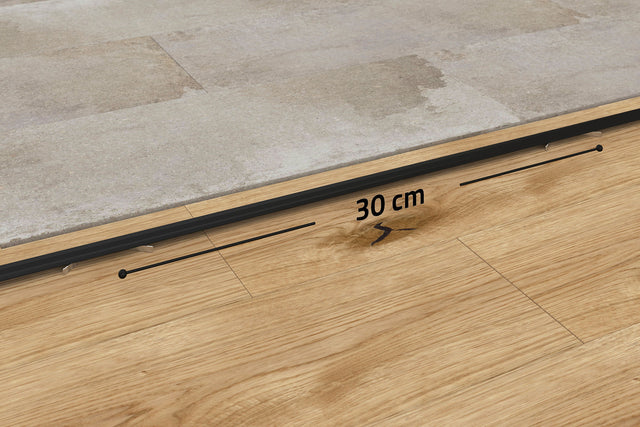

Step 5

Insert mounting clips every 30 cm in the end strip.

ONLY FOR FLOATING FLOORS: Before installing the profiles, apply some flexible installation adhesive or silicone into the end joint to fix the profile securely.

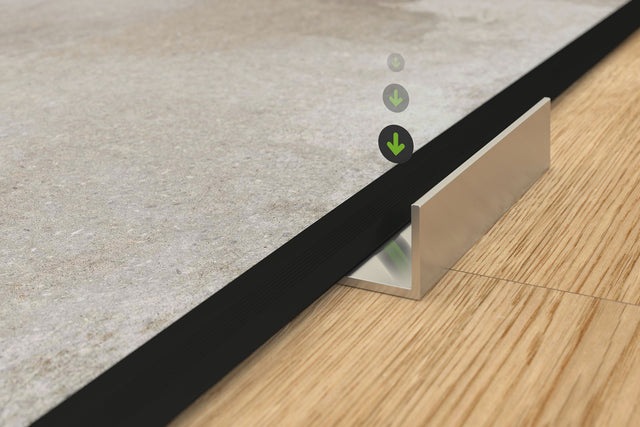

Step 6

The transition profile with the inserted mounting clips is now brought into the mounting position on the transition joint. With the assembly aid, the assembly clips are carefully spreaded out by using the assembly aid to apply the assembly clips towards the transition profile.

Step 7

As soon as the clamping process is completed, the end profile is pressed down and the assembly aid is removed. Now the tensioning and assembly process is repeated until all assembly clips on an transition profile are tensioned and countersunk. For any corrections the transition profile can be removed from the connection joint at any time.

Step 8

The transition profile is installed. After a brief inspection, the next section can be assembled.